Screw Oil Press

The Screw Oil Press Machine is a widely used oil extraction system known for its reliability, efficiency, and ability to handle various types of oilseeds. Its simple design and robust construction make it a popular choice for various-scale edible oil production lines. This screw oil machine uses a mechanical screw to compress and extract oil from seeds, delivering high oil yields with minimal waste. The Screw Oil Press Machine can handle a wide variety of oilseeds, such as peanuts, sunflower seeds, soybeans, rapeseeds (canola), sesame seeds, coconut meat, palm kernels, flaxseeds, mustard seeds, etc.Screw Oil Press Machine Applications

The Screw Oil Press Machine is an all-purpose solution for extracting oil from various raw materials, such as:

Soft Seeds: Soybeans, peanuts, sunflower seeds, rapeseeds, and sesame seeds.

Hard Seeds/Nuts: Palm kernels, coconut meat, walnuts, and almonds.

Specialty Seeds: Flaxseeds, chia seeds, and moringa seeds.

Dual-Stage Pressing (Optional): For seeds with high oil content, the screw oil press machine can perform a second pressing stage for even greater oil extraction.

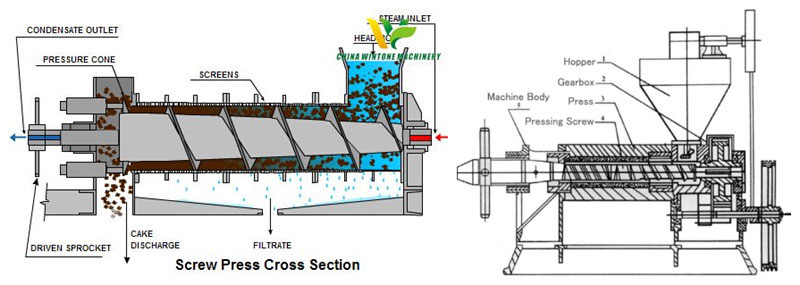

The Screw Oil Press Machine Structure Details

Oilseed Feeding Hopper

Automatically regulates the flow of seeds into the screw oil pressing chamber, ensuring steady operation and preventing overloading.

Oil Pressing Chamber

Houses a robust screw shaft that compresses oilseeds under high pressure, extracting oil efficiently.

Screw Shaft

This core component is precision-engineered and designed with optimal grooves and pitch for efficient seed crushing and oil extraction.

Heater and Temperature Control

Preheats the seeds to the desired temperature, improving oil flow and quality. Adjustable settings for different seed types.

Crude Oil Outlet

Directs extracted oil into a collection container or filtration system.

Oilcake Outlet

Discharges compressed oilseed residue (oil cake) for easy collection and reuse.

Control Panel

Allows operators to monitor and adjust pressing parameters such as temperature and pressing speed.

The Screw Oil Press Machine Working Process

1. Oilseed Preparation

Oilseeds are cleaned and dried to remove impurities and ensure smooth pressing.

2. Oilseed Feeding

Prepared oilseeds are fed into the screw press machine through the hopper.

3. Oil Pressing

The screw shaft rotates, crushing the seeds and creating high pressure within the pressing chamber. This pressure extracts oil while separating the solid residue (oil cake).

4. Heating and Oil Extraction

The integrated heater maintains an optimal temperature, reducing oil viscosity and enhancing extraction.

5. Crude Oil Collection

The extracted oil flows through the outlet into a collection container or filtration system.

6. Residue Discharge

The oilseed cake is expelled automatically, ready for further processing or disposal.

Screw Oil Press Models And Technical Data

| Model | Capacity | Power | Dimension | Weight |

| 6YL-68 | 1-1.5 T/D | 5.5 KW | 880*480*660 MM | 140 KG |

| 6YL-80 | 3-4 T/D | 7.5 KW | 1810*560*735 MM | 330 KG |

| 6YL-95 | 3-5 T/D | 7.5 KW | 1910*610*765 MM | 420 KG |

| 6YL-120 | 4-7 T/D | 11 KW | 2060*610*760 MM | 580 KG |

| 6YL-120C | 6-8 T/D | 15 KW | 2100*700*770 MM | 580 KG |

| 6YL-130 | 9-12 T/D | 18.5 KW | 2280*700*770 MM | 760 KG |

| 6YL-160 | 15-20 T/D | 22 KW | 2400*700* 770 MM | 960 KG |