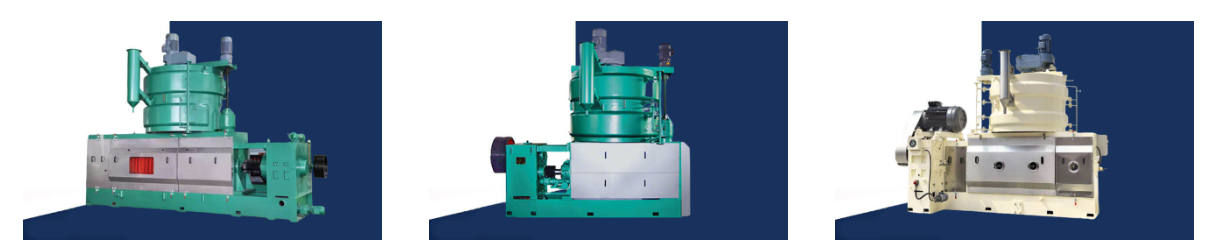

Large Scale Oil Press Machine

This ZY series large mechanical oil press machine uses physical mechanical pressing to press oil out from high oil-content oilseeds, such as peanuts, sunflower seeds, castor, cotton seeds, rape seeds, sunflower seeds, etc. Single oil press machine capacity ranges from 10T/D to 200T/D. The oil press machine is equipped with steaming and roasting equipment which can heat the materials to an optimum temperature before being fed to the pressing cage to achieve automatic edible oil production. It is the best choice of oil press machine for continuous production in the edible oil production line.Large Scale Oil Press Machine is designed to extract high-quality oil while preserving its nutritional value and natural properties. Ideal for large-scale oil processing plants, this innovative machine combines advanced pressing technology with low-temperature processing to maximize oil yield and produce superior-quality oil.

ZY Series Oil Press Machine Features

1. Large Processing Capacity ranges from 10T/D to 200T/D.

2. Perfect Design, Easy Operation, and Durable Service.

3. Combined Steaming and Cooking.

4. Automatic and Continuous Production.

5. Higher quality oil and oil cake. Steady oil yield

6. Better adaptability, and flexible production.

ZY Series Large Scale Oil Press Machine Application

This ZY series screw oil press machine can be used alone to press various oilseed, or used for pre-pressing and twice pressing in the edible oil production lines. Depending on the type of oilseed, we use different methods of oil pressing.

The Basic Edible Oil Press Process.

1. The conventional oil mill plant: oilseeds – Cooking – pressing – crude oil

2. Hot Press oil mill plant: oilseeds — roasting – pressing – Filtration – Edible Oil

3. Cold press oil mill plant: oilseeds — full oilseeds press — filter — cold pressed oil

Single Pressing: Also called full pressing. The oil could be extracted as much as possible. The oil residual in cake is around 5-7%.

Pre-pressing: 70% of the oil will be extracted, and the oil residual in the cake is around 15-18%.

Hot Pressing: Cook the oil seeds before pressing to extract more oil.

Cold Pressing: Keep the temperature between 60 and 70℃ to prevent protein denaturation.

Large scale oil press machine can process over 20 kinds of oilseeds, such as peanut, soybean, rapeseed, cottonseed, sesame, sunflower, grainy oil plant seeds as well as corn germ, etc. into a high-quality edible oil.

Large Scale Oil Press Machines Parameters

| Model | Capacity (TPD) |

Dry cake residual oil rate |

Power (kw) |

Size (mm) |

Weight (kg) |

|---|---|---|---|---|---|

| zx-23 | 20-25 | 5-8% | 45 | 5000*2580*2700 | 8000 |

| zx-24 | 50-60 | 10-15% | 75 | 3705*1040*2800 | 10000 |

| zx-25 | 90-100 | 7-9 % | 115 | 4100×2270×3850 | 11000 |

| zx-26 | 220-260 | 16-20 % | 125 | 4100×2270×3850 | 11000 |

| zx-27 | 150-300 | 13-16% | 200 | 5950*1477*3250 | 17500 |